Production

Molding room

- Aluminum Molds,

- Metal Injection Molds,

- Plastic Injection Molds,

- Trim Molds. .

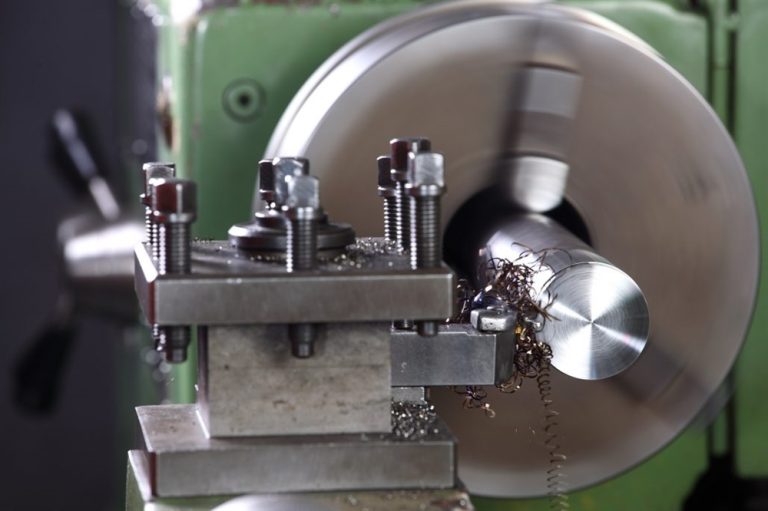

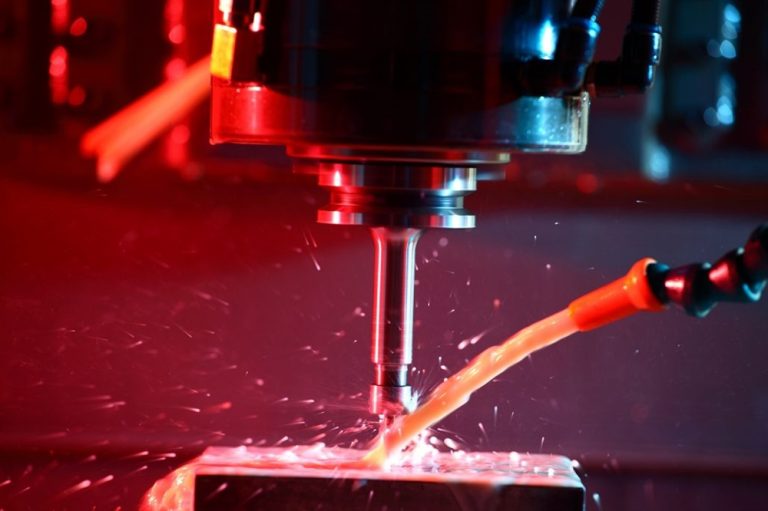

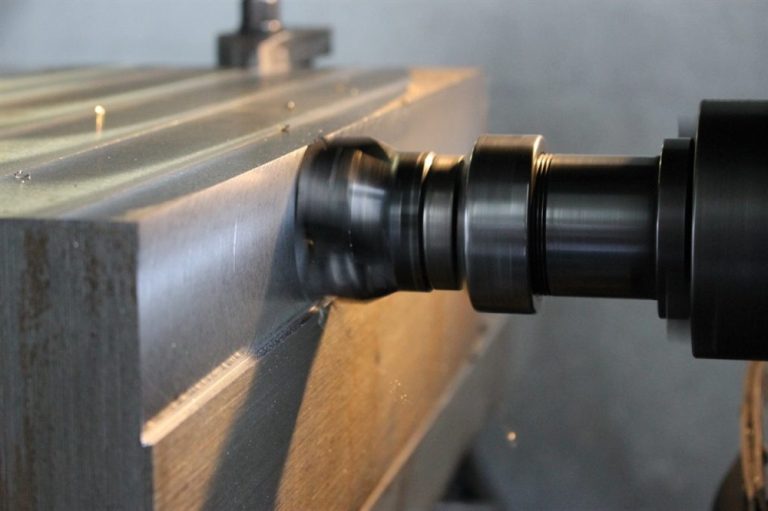

For CNC turning and mold manufacturing; we have the necessary conventional machines such as 3-axis machining centers, CAD/CAM system, wire and plunge erosion. These are;

- 3 CNC (600 X 600) Vertical Machining Centers

- 1 CNC (580 X 450) Vertical Machining Center

- 1 Unit CNC (300 X 600 x 6000) Horizontal Turning Machining Center

- 1 Unit Joemars Wire Erosion (300 x 450)

- 2 Units Joemars Immersion Erosion

- 1 Unit Joemars Quick Drilling Machine (354 x 256)

- 4 Units Universal Milling Cutter

- 1 Unit Manual Turning Lathe

- 1 Unit Surface Grinding

- 1 Unit Radial Drill.

Foundry

In order to minimize human error in the foundry, as KAYA-PEN, we use fully automatic robotic injection machines and minimize faulty production. All health and safety precautions have been taken in the foundry.

In our Machine Park;

• 6 Units 400 Tons Pressure Capacity Fully Automatic Robotic Aluminum Injection

• 3 Units 160 Tons Pressure Capacity Fully Automatic Zamak Injection

• 7 Units 100 Ton Pressure Capacity Fully Automatic Zamak Injection

• 2 Units 50 Ton Pressure Capacity Fully Automatic Zamak Injection

• 2 Units Zamak Serial Injection (Part Weight Max: 80 gr)

Plastic Injection

As KAYA-PEN, we reduce the time and cost of production with Plastic Injection. The resulting products are of high quality and durable.

- 1 Unit 300 Tons Pressure Capacity Fully Automatic Plastic Injection

- 1 Unit 250 Tons Pressure Capacity Fully Automatic Plastic Injection

- 1 Unit 200 Tons Pressure Capacity Fully Automatic Plastic Injection

- 1 Unit 190 Tons Pressure Capacity Fully Automatic Plastic Injection

- 1 Unit 175 Tons Pressure Capacity Fully Automatic Plastic Injection

- 1 Unit 150 Tons Pressure Capacity Fully Automatic Plastic Injection

Surface Treatment Line

As KAYA-PEN, we increase the durability of the product against external factors at the surface treatment line.

In our Machine Park;

• 6 Units Manual Sanding Machines,

• 2 Units Semi-Automatic Sanding Machines

• 6 Units Manual Polishing Machines

• 4 Units Trowal Surface Cleaning Centers

Alkaline Zinc Coating Machine

As KAYA-PEN, we provide permanent, even and smooth coating with our Alkaline Zinc Coating Machines.

In our Machine Park;

• Automatic Alkaline Zinc Plating Machine with 3 Robots

• Automatic Drying Machine with 2 Robots.

Electrostatic Powder Coating Line

• 1 Unit Manual Powder Coating Booth

• 1 Unit Robotic Chromating Machine

Quality Laboratory

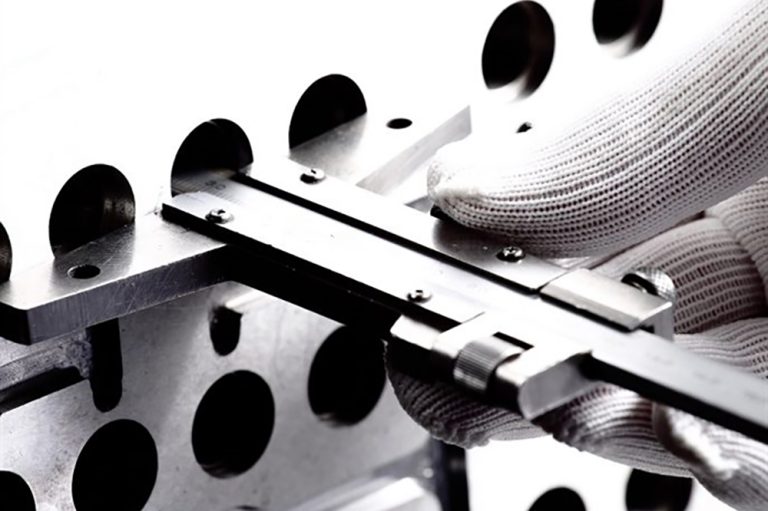

We, KAYA-PEN, have a quality laboratory to test and measure parts. Our quality control team working in our laboratory consists of experienced engineers, laborants and technicians.

Internal Tests

• Life Tests

• Dimensional Measurements

• Functionality Checks / Tests

• Non-Destructive Paint Thickness Control

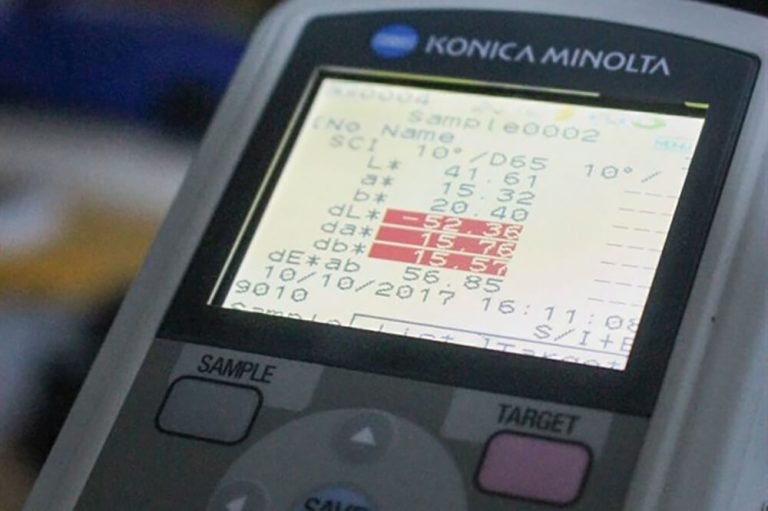

• Color Measurement with Spectrophotometer

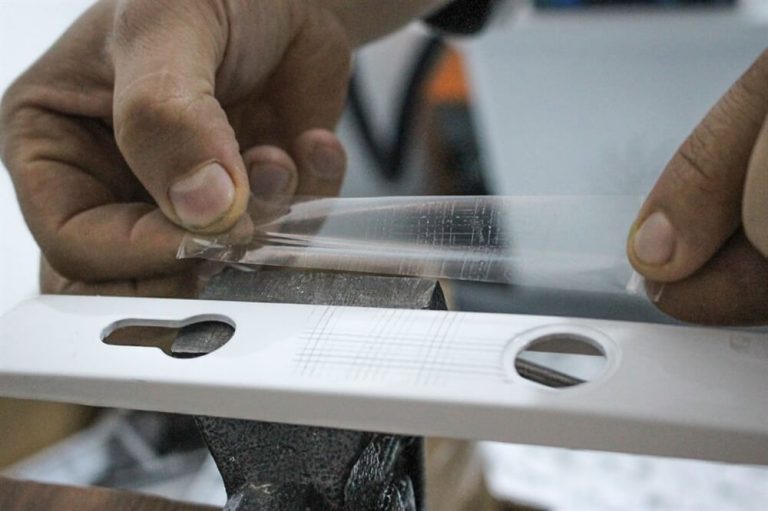

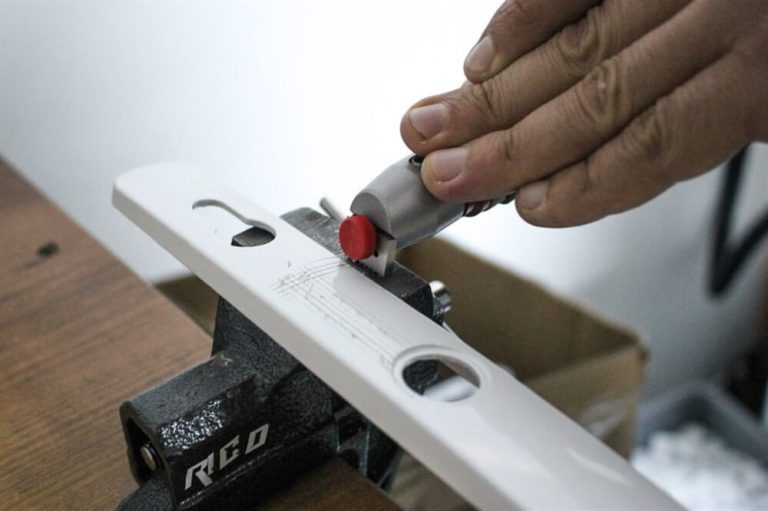

• EN ISO 2409 Paints and Varnishes – Cross-Cut Test

• Chemical Analysis with Spectrometer

External Tests

• Non-Destructive Testing (X-Ray)

• Corrosion Test (Salt Spray Test in Artificial Atmosphere)

• EN ISO 9227 Corrosion Tests-Salt Spray Tests in Artificial Atmospheres

• EN 1670 Building Hardware – Corrosion Resistance – Requirements and Test Methods

Assembly and Packing Line

Shipping and Logistics

As KAYA-PEN, we deliver the demanded amount of products on time and quick to every corner of Turkey, either with our own domestic transportation company vehicles or with contractual transportation companies.

For our foreign customers we deliver the products on time, quick and complete by land, by sea and by airways in accordance with the delivery conditions of INCOTERM 2010.

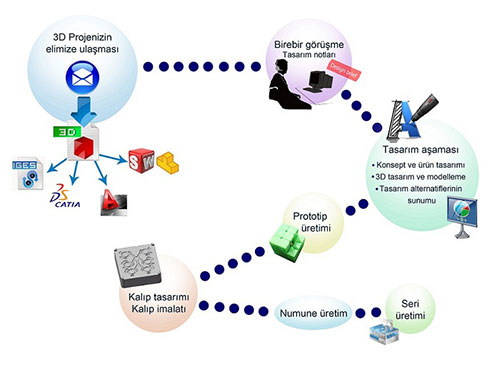

R&D Project Process

Research and Development, or R&D for short, is one of the hottest topics today. R&D includes creative works based on a systematic basis in order to increase the knowledge of the person, society and culture so that this accumulation can make way for new applications.

As KAYA-PEN R&D, in our journey where we set out to improve our production quality we can define it as systematic works done for the purpose of restructuring products created with our existing knowledge by improving with innovative ideas and programs or by obtaining new information that will enable the production of new products or a prototype product designed by using up-to-date programs in the computer environment.

The expert personnel and qualified support personnel who are actively working in R&D activities are engaged in planning, managing, monitoring, evaluating and supporting the scientific and technical aspects of R&D activities. Our “R&D personnel” consists of people who have bachelor degrees and the necessary certificates, licenses, certificates of competence, etc. in the field of work.

In the light of all these, our company’s R&D department consists of technicians, operators and engineers. We are moving forward with our team who are open to innovative ideas and have a team spirit. Our R&D is the product of a collaborative work and our main goal is determined as “Every idea is worth hearing”.