Molding Room

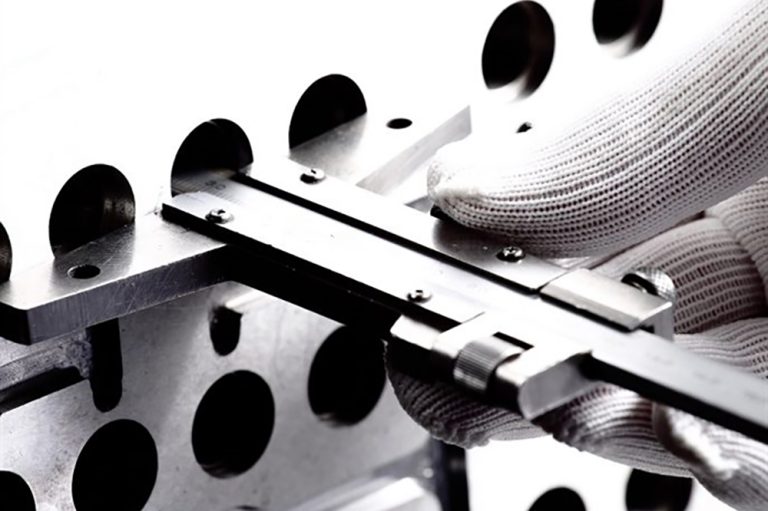

At KAYA-PEN, our main focus in the molding room is to ensure customer satisfaction. To achieve this, we blend our experience with the latest and superior technologies to process molds with the utmost precision and care. We take care of time, price, and quality management for our customers. One of the benefits we offer to our customers is that we produce our molds in-house.These are;

- Aluminum Molds,

- Metal Injection Molds,

- Plastic Injection Molds,

- Trim Molds.

In our machine park;

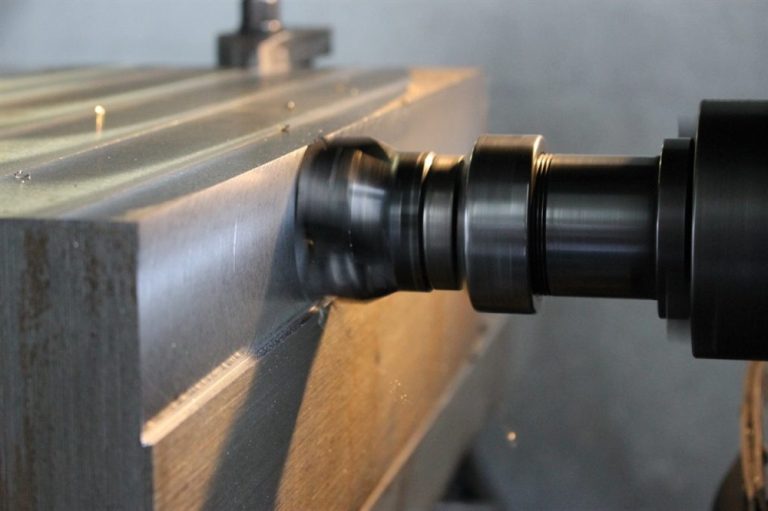

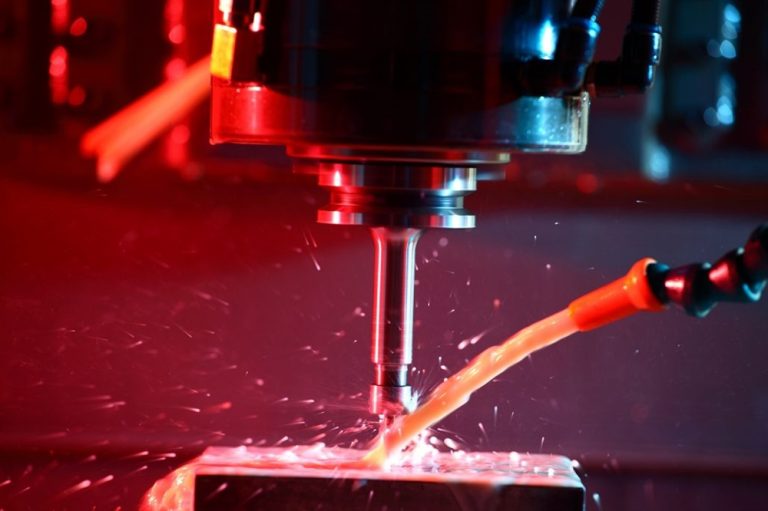

For CNC turning and mold manufacturing; we have the necessary conventional machines such as 3-axis machining centers, CAD/CAM system, wire, and plunge erosion. These are;

- 3 CNC (600 X 600) Vertical Machining Centers

- 1 CNC (580 X 450) Vertical Machining Center

- 1 Unit CNC (300 X 600 x 6000) Horizontal Turning Machining Center

- 1 Unit Joemars Wire Erosion (300 x 450)

- 2 Units Joemars Immersion Erosion

- 1 Unit Joemars Quick Drilling Machine (354 x 256)

- 4 Units of Universal Milling Cutter

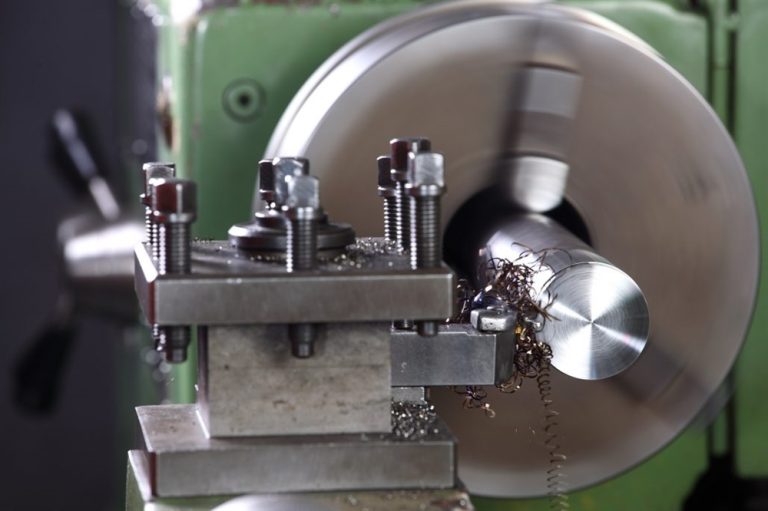

- 1 Unit Manual Turning Lathe

- 1 Unit Surface Grinding

- 1 Unit Radial Drill.